After receiving the necessary documents and project presentation, our team will try to review your request as soon as possible, and leading experts will offer the best options for project funding.

- Types of thermal power plants

- Engineering design of thermal power plants: principles and stages

- Key stages of the construction of thermal power plants

- Modernization of thermal power plant

- International EPC-contracting for construction of TPPs

However, coal, brown coal, oil, natural gas and biomass remain affordable and widespread energy sources in many regions of the world.

The design and construction of thermal power plants (TPPs) continues to cover the growing demand for electric and thermal energy in the future.

Types of thermal power plants

A thermal power plant is a facility that transforms thermal energy into electrical energy.Thermal energy usually comes from burning fuel, but there are also thermal power plants that can operate on geothermal and solar energy. The main types of fuel for thermal power plants are coal, fuel oil, natural gas, biomass, biogas, as well as industrial or municipal waste.

The power unit consists of a steam boiler, (diesel engine), turbines, generator, condenser, water pump, transformer and auxiliary equipment (e.g. coal mills, heat exchangers, pumps or fans).

An important role in modern thermal power plants is played by flue gas desulfurization and denitrification equipment, water tanks with degassers, etc.

Conventional TPPs

Conventional thermal power plants generate heat by releasing chemical energy contained in fossil fuels (gas, coal, fuel oil) through the combustion process.The following types of conventional thermal power plants are available:

• Gas turbine power plants with gas turbines.

• Steam turbine power plants with steam turbines.

• Combined cycle power plants with gas and steam turbines and a waste heat boiler.

• Thermal power plants based on internal combustion engines.

The most common are steam thermal power plants (steam at 500-550 C and 100-200 atm), which use fuel oil (36% efficiency), coal (47% efficiency) and natural gas. Combined cycle power plants (60% efficiency) are the most technically advanced.

To increase the efficiency of thermal power plants, new technologies are being developed related to high-strength materials capable of withstanding higher pressure (350 atm) and temperature of about 650-700 C.

Biomass thermal power plants

Biomass thermal power plants generate heat by releasing the chemical energy contained in the biomass (agricultural and forestry waste, municipal solid waste, biofuel) through the combustion process.These plants differ little from conventional TPPs described above.

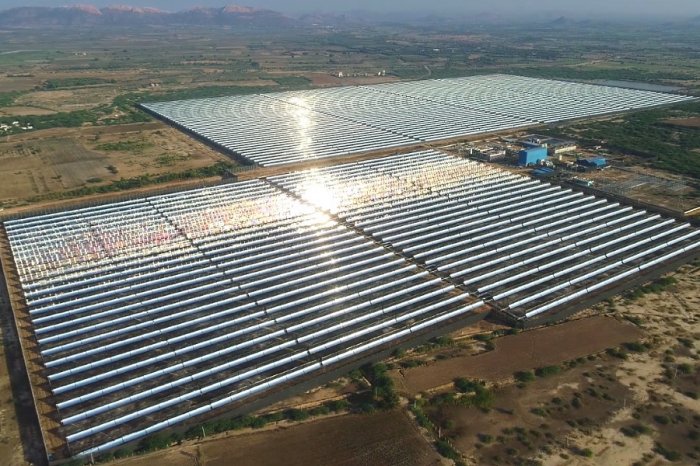

Solar thermal power plants

Solar thermal power plants receive heat by directly capturing solar energy and concentrating it using mirrors, in line or at the focus through which fluid circulates (oil, salt solutions).Geothermal power plant

Innovative geothermal power plants receive heat from geothermal sources inside the Earth. These facilities can only be built in certain geographical areas, which significantly limits their application.Combined heat and power plant

Power generation is associated with the combined production of useful heat.Cogeneration is a technological process for the simultaneous generation of electricity and heat in the form of steam. Systems of this kind are called cogeneration plants.

Combined heat and power (CHP) plant is a plant that produces electricity and heat in the form of steam at high temperature. This steam is used in district heating networks or industrial processes.

Coal-fired thermal power plants are the most common in Europe. They use lignite or coal as fuel. These power plants were built mainly in the second half of the 20th century, and currently most of them require environmental modernization.

Global investments in the construction of coal-fired thermal power plants are declining today as a result of depletion of fossil fuel reserves and stricter environmental legislation. This trend is observed both in the EU and in other regions of the world.

Steam turbine solar power plants and geothermal TPPs, which are based on renewable energy sources, are much more promising areas of energy development.

In general, the efficiency of thermal power plants rarely exceeds 55-60%. For this reason, energy companies around the world are looking for the best ways to modernize thermal power plants and increase their efficiency.

Advantages of combined cycle thermal power plants

In recent years, there has been a tendency in world practice to use the so-called combined cycle in the construction of new TPPs, as well as in the modernization of old facilities.When designing a thermal power plant, an engineering company must ensure the lowest possible cost of electricity production and its maximum efficiency:

• The use of large power units, which can significantly increase the efficiency of the system and reduce construction costs.

• Ensuring optimal steam parameters (high pressure and high temperature), which requires expensive materials that are resistant to extreme conditions.

• Proper design and ensuring optimal operating conditions for the equipment.

• Minimization of energy loss and reuse of waste energy.

Among the main reasons for the growing popularity of combined cycle power plants is a very high efficiency. Other advantages of combined cycle thermal power plants are high power, relatively fast construction, as well as low costs for the construction, operation and maintenance of equipment.

The high efficiency of combined cycle plants is explained by the combination of two thermodynamic cycles, the Brighton cycle and the Rankine cycle, which increases the efficiency of the power plant as a whole. An important structural element of combined cycle power plants is a waste heat boiler, which is used to generate superheated steam.

The efficiency of steam and gas turbines, used separately for generating electricity, usually does not exceed 30%.

Combined cycle thermal power plants use fuel energy with an efficiency of up to 50-60%.

In old-type thermal power plants, the efficiency is usually around 33%.

This means that 2/3 of the energy is released into the atmosphere in the form of waste heat.

The principle of operation of combined cycle thermal power plants

Fuel (most often natural gas) is supplied to the combustion chamber. The resulting combustion products with a temperature of 900-1200 C pass through the turbine blades, and the mechanical energy of the shaft is transmitted to the first electric generator.Since flue gases release only part of their energy when passing through a gas turbine, the cycle efficiency at this stage is up to 35-37%. At the exit of the turbine, the flue gases still have a high temperature in the range of 500-600 C. This temperature is considered high enough to heat water and produce steam to rotate the steam turbine.

When passing through the blades of a steam turbine, the steam expands, as a result of which the thermal energy is converted into mechanical energy. The mechanical energy produced at this stage is used by the second generator to produce additional electrical energy.

Thanks to this cycle, an additional 20% of electricity is generated. This leads to an overall increase in the efficiency of the power plant by approximately 60%. For comparison, conventional thermal power plants equipped with gas turbines have an efficiency of up to 40%.

Engineering design of thermal power plants: principles and stages

Thermal power plants are an important element of any industrial complexes.These facilities are notable for their high cost and technical complexity, which requires a professional approach to engineering design and construction.

We highlight the following principles:

• Professionalism. The engineering design of thermal power plants is carried out by large institutes and engineering firms. As a rule, they have significant experience in implementing energy projects.

• A complex approach. One and the same organization is developing the whole range of TPP subsystems, including its electrical and auxiliary equipment, access roads and communications.

• Continuity. The design of a thermal power plant should be based on experience in the construction and operation of similar facilities. Engineering firms collect and analyze all the data during the construction process, and subsequently use them for maintenance and modernization.

• Typical design. One of the design principles is to use fragments that have been successfully implemented in other projects. Although each project is individual, it can include typical design solutions that are time-tested.

• Prefabrication. The current trend in the construction of thermal power plants is the active use of prefabricated modular structures and factory-made devices. These include complete switchboards, control panels and building elements. This greatly simplifies design and speeds up construction and installation.

• Environmental protection. Thermal power plants have a significant negative impact on the environment, mainly on the atmosphere. Today, engineering companies give priority to the environmental performance of facilities.

Before the actual start of work, a detailed program is developed. It includes all types of activities, up to the commercial operation of a TPP. The construction of thermal power plants is preceded by numerous administrative procedures, permits, environmental studies, etc.

The implementation of a thermal power plant project includes pre-project activities and feasibility studies, design of TPP structures and equipment, a complex of construction and electrical installation works, testing and commissioning. In accordance with the terms of the contract, the contractor provides staff training, operation and maintenance of the facility.

Feasibility study

Modern thermal power plants are complex facilities worth several billion euros.The success of the TPP project is laid at the engineering design stage. Obviously, each technical solution must meet the goals of the customer.

The optimal solution in each case must satisfy the quality requirements at the lowest possible cost. GCAM company individually approaches each project.

Equipment requirements for thermal power plants include:

• Economic efficiency, which is estimated on the basis of the cost of construction and operation, annual costs of repair and maintenance.

• Reliability, that is, the ability of the equipment to perform specified functions under certain operating conditions.

• Convenience of operation, that is, the minimum number of operations performed by personnel during the daily operation of equipment.

• The possibility of subsequent expansion and modernization of the facility.

• Reliability and safety of the operation.

A thermal power plant consists of several parts (subsystems), including heating networks, electrical, transport and auxiliary subsystems.

Modern technologies allow performing both complex and local optimization of each of these subsystems.

The choice of fuel for a thermal power plant

The key issue in the design of thermal power plants is the choice of fuel.This will determine the type of process and equipment. Each of the options has advantages and disadvantages, which are weighed at the stage of pre-project activities and planning.

The main types of fuel for thermal power plants:

• Coal. This is a solid fossil fuel, consisting mainly of carbon and other elements, the percentage of which varies depending on the place of production. Historically, coal has been the main fuel used in European thermal power plants due to its vast coal reserves. But since the beginning of the 21st century, the environmental impact caused by the high amount of carbon dioxide emitted into the atmosphere has reduced coal use as a fuel.

• Fuel oil. This type of fuel is a low-value product obtained by fractional distillation of crude oil in refineries. Lighter fractions are used for aircraft and other vehicles, while heavy fractions are more suitable for use as a fuel in industry. Liquid hydrocarbons are an excellent source of energy; they are easy to handle, store and use.

• Gas. Gaseous hydrocarbons are obtained from natural gas reserves or produced by the chemical industry. Thermal power plants mainly use natural gas, which is a combination of light hydrocarbons, mainly methane. Gas does not occupy an expensive storage space because it is transported by pipeline directly to the power plant. Natural gas produces less carbon dioxide than other fossil fuels.

Thermal power plants have an average service life of at least 20 years, but they are usually designed for continuous operation of more than 25 years.

Taking into account the long term of operation, forecasting prices and fuel reserves will be one of the most determining factors when choosing a technological process.

Coal is considered a more affordable and economically viable fuel. However, coal has serious disadvantages associated with the environmental impact of the process and its effectiveness. In each case, an individual approach is needed.

Choosing a place for the construction

Power plants usually require a large area for construction.Some elements, such as fuel storage, railway stations and slag dumps, can be moved outside the thermal power plant. In any case, the construction site must ensure the smooth functioning of the power plant for at least 25 years.

The choice of location for the construction of a thermal power plant should correspond to the type and design features of the facility.

This should be consistent with the plans for the development of the energy system as a whole.

The most suitable place for the construction of a thermal power plant is determined taking into account the convenience of transporting fuel and the availability of water sources for cooling.

The requirements for the construction site are as follows:

• Sufficient area.

• Proximity to the source of thermal coal.

• Proximity to natural water sources.

• Proximity to consumers of electricity and heat.

• Proximity to transport routes.

• Security for neighbors.

Coal mining regions are best suited for the construction of coal-fired power plants. In addition, the construction site should have a developed railway network capable of providing fuel to the facility.

When studying the site, seismic activity, climatic features, groundwater level, soil condition and many other factors are taken into account.

Layout of thermal power plants

The most important condition for the successful implementation of the project is the correct layout of the thermal power plant.Engineers should offer a rational arrangement of structures to ensure the efficient and safe operation of a thermal power plant.

This is one of the most difficult aspects of the design of TPPs, which requires the participation of a multidisciplinary team of electrical engineers, architects, technologists, ecologists, etc.

The layout of the power plant must take into account many factors, including topography, location of the water source, wind direction, etc. In particular, improper location of equipment relative to the wind can lead to serious negative consequences. Wind from a power plant can cause air pollution in nearby communities.

Distances between cooling towers, water tanks, and other structures must meet certain standards. The rationality of the layout is also determined by the features of the transport network and the fire system.

The layout principles of thermal power plants include:

• Proximity to the reservoir.

• Rational placement of access roads, power lines and heating networks.

• Rational placement of auxiliary facilities to ensure unhindered repair and maintenance.

• The most efficient use of the site allocated for construction.

• Possibility of further modernization of the power plant with minimal changes and costs.

Finally, the layout of the TPP should ensure stable and safe operation of the facility. At the design stage, our engineers pay great attention to the placement of the fire system and security devices.

Selection of equipment for a thermal power plant

Engineering design of thermal power plants includes the selection of the technological scheme (communication between the units), the selection of the main equipment, the design of the thermal system, the selection of auxiliary technological equipment and the design of auxiliary structures.The main power equipment includes steam generators and turbines.

If possible, the equipment should be chosen of the same type, as this simplifies construction and optimizes operation and repair. The choice of turbines installed in thermal power plants is determined depending on the specific type of facility and its capacity.

General principles for choosing auxiliary equipment for thermal power plants:

• The equipment should provide long-term operation of the power plant with rated power.

• Reliable and time-tested technologies should reduce the risk of unscheduled shutdowns of a power plant.

• Failure of auxiliary equipment must not lead to any damage to boilers, turbines or steam generators.

We work closely with leading research centers to provide you with the latest technology and equipment.

Modern means of automation of engineering design automation tools that accelerate the development of technical documentation and eliminate errors.

Each of our solutions is based on knowledge multiplied by advanced technologies.

Key stages of the construction of thermal power plants

Construction and installation work is carried out in accordance with a standard multi-stage plan.The construction of thermal power plants includes the following stages:

Preliminary work

First of all, experts prepare the construction site to ensure safe and high-quality subsequent construction and installation works.• Installation of temporary construction fences to restrict access to the site.

• Construction of premises for workers involved in construction.

• Adaptation of landscape to meet project requirements.

The purpose of this stage is to provide the site with all the necessary materials and equipment.

The structures will be constructed in such a way that they provide sufficient space for installation and maintenance work, guaranteeing complete safety and a long service life of the facility.

All buildings and administrative premises will be designed in accordance with their purpose. When designing buildings, the greatest attention is paid to fire protection, sound insulation, as well as physical safety of personnel and equipment.

Preference is given to highly functional buildings with minimal visual impact. Architectural work includes environmental impact studies to ensure that projects meet all environmental requirements.

The main electrical equipment of the TPP includes the following:

• AC / DC cabinets.

• Auxiliary transformers of medium and low voltage.

• Turbines, recovery boiler and other generating equipment.

The chimney of a power plant is made of concrete, and is built on a high-strength reinforced concrete foundation. The area under the foundation will be filled with stones to form a solid base below ground level.

Platforms for personnel access and stairs are designed in such a way as to ensure ease of use and maintenance of equipment.

The main control building of the TPP will contain:

• Central control room.

• Electronic equipment for control and automation.

• Offices and common areas for operators.

Offices, locker rooms, a workshop and a warehouse can be located in technical structures.

Communications consist of supports for pipes and cables, power lines and other communication equipment that ensures the smooth operation of thermal power plants.

• Optimal arrangement of different zones of the power plant minimizes the length of communications and avoids complex paths of interconnected lines.

• The combination of wires and pipelines of different systems in the same channel minimizes the number of necessary supports.

Construction of drainage systems

Efficient drainage systems ensure the safe operation of the power plant, especially in humid climates. Underground drainage systems are one of the first to be built.Particular attention is paid to drains intended for rainwater, domestic wastewater, as well as waters contaminated with transformer oil and chemical agents.

Stormwater drainage system

This drainage system collects rainwater from roofs, internal roads and areas of a power plant that are not contaminated with transformer oil or chemicals.This system is built on the basis of channels and pipelines.

Rain water is directed into drainage channels or pipes laid at a certain angle of inclination, which is calculated individually.

Sanitary drainage system

This system is designed to drain domestic wastewater from the premises of a power plant. The sanitary drainage system is usually connected to local wastewater treatment plants.Oil drainage system

Water contaminated with oils as a result of daily operation and maintenance of thermal power plants falls into a special drainage system. From here, polluted water enters the separation pool.When using oil transformers, there is a need for special drainage systems to collect water contaminated with transformer oil.

Chemical drainage system

Chemical waste that is harmful to building materials must undergo special treatment in the neutralization pool.Neutralized waste is discharged into a special pool for mixing and control. Chemical drainage pipes must be acid resistant.

Underground utilities construction

At the initial stages of the construction of thermal power plants, underground utilities are laid.They are necessary for the functioning of the fire water supply system, outdoor lighting systems, security systems and so on.

Fire water supply system

A fire extinguishing system is being built, which will cover all the main buildings of a thermal power plant with an underground pipe system. Water will be supplied to special tanks.Power plant outdoor lighting

The lighting system of TPPs is individually designed to ensure the convenience of equipment operation and personnel safety. The most reliable option is the laying of outdoor lighting cable in underground cable ducts.Compressed air pipes

Compressed air pipes between buildings will either pass through high-strength piping systems usually laid at great depths.Construction of access roads

The construction of access roads will require heavy equipment for excavation, leveling, compaction and asphalting. Excavators, bulldozers, pavers and heavy trucks are used in road construction.Soil obtained as a result of earthwork can be used to level the construction site. Excess soil will be transported to an authorized landfill designated for these purposes. If the terrain is very rocky, road construction may require controlled blasting.

Access to a power plant usually requires permission to lay roads through farms and settlements.

This stage of construction is legally complex and very responsible.

Construction of the main components of a thermal power plant

This stage begins with preparing the land, cleaning the construction site and filling it with land to a specified level. In order to optimize earthwork, it may be necessary to divide the site into two zones that lie at different levels.The construction phase of the main components of the thermal power plant includes the installation of temporary warehouses and premises for staff and the preparation of temporary access roads.

Excavations are being carried out for the foundations of buildings and equipment of a thermal power plant (gas and steam turbines, waste heat boilers, pumps, tanks, transformers, cooling towers). These works can be carried out in parallel with the construction of drainage systems, as well as pipelines and underground cable channels.

The main structures of thermal power plants are built from reinforced concrete and steel structures.

Reinforced concrete structures

Depending on the distance to the nearest concrete plant, a temporary plant with appropriate storage bins may be required.Concrete structures will include auxiliary buildings for maintenance personnel and some other auxiliary structures requiring high insulation.

Typically, these are structures based on rigid frames formed by beams, columns and a roof of monolithic reinforced concrete slabs, with facade walls and partitions. In structures with roofs based on concrete slabs, an appropriate waterproofing system is designed.

Steel structures

Large-area buildings, such as workshops and warehouses, usually have a steel structure.They must meet a number of specific requirements:

• The supporting frame will be made of durable structural steel.

• Walls and ceilings must be covered with a layer of insulation to meet all requirements.

• Steel structures will be protected against corrosion by zinc phosphate primers or other suitable products.

Interior walls

The internal walls in the premises of the power plant can be built of bricks or made in the form of light partitions, depending on the project.Flooring

Flooring will be designed to meet the load and operating conditions of the premises specified in the project.Like other elements of buildings and structures, flooring is made of durable materials with a long service life.

Basement

Underground structures of a thermal power plant that may be flooded with water will be properly sealed. In addition, special reservoirs and drainage systems will be developed to prevent water seepage.Lighting

Office space and control room are equipped with false ceilings made of refractory material. The design of ceiling lights should ensure safety and ease of maintenance.Doors and windows

Large maintenance doors must be sliding. All emergency exits will be equipped with crash bars for quick and safe evacuation of personnel. Window frames will be made of steel or PVC, depending on the purpose of the room.Indoor equipment

Each building should be equipped in accordance with the functions performed (lighting, low-voltage electricity, heating, air conditioning, ventilation, communication) as necessary.Installation of equipment for a thermal power plant

Installation of equipment is carried out after completion of the main construction works:• Assembly of mechanical equipment followed by cabling.

• Assembly and connection of electrical components and devices.

To assemble mechanical equipment, especially a waste heat boiler, it is necessary to prepare a pre-assembly area where components are assembled using lifting devices and welding machines.

The pre-assembly area optimizes lifting operations and allows welding to be performed under more favorable controlled conditions than at the installation site. The scope of pre-assembly work depends on the condition of the equipment that is being delivered to the construction site.

As a rule, bulky equipment is delivered to remote sites by trucks in disassembled form. Therefore, pre-assembly work may take longer than with the delivery of finished units.

After completion of the mechanical assembly, hydraulic tests of the equipment circuits are carried out. Before the first start-up, purging and chemical cleaning of the boilers is carried out. For this, demineralized water with chemical reagents is used.

Cleaning solutions are used for a certain time.

After completion of the process, the spent solutions are disposed of in accordance with environmental requirements.

Lifting and assembly and welding equipment includes:

• Medium tonnage cranes for lifting the components of the recovery boiler, and gas turbines.

• An overhead crane that is temporarily mounted in a steam turbine hall to assemble a steam turbine, generator, and auxiliary equipment.

• Construction hoists and small cranes of various designs.

• Equipment for metal inert gas welding (MIG).

• Induction devices for heat treatment of welds.

• Special equipment for quality control, including X-ray machines, ultrasound scanners, luminescent penetrating liquids, etc.

Construction of a high voltage power line

Electricity is delivered to consumers using high-voltage power lines, which must be connected to the finished power plant in the most rational and safe way.The construction of a high voltage power line includes the following steps:

Construction plan

The plan should include marking the location of each of the power lines, the location of power transmission towers with the dimensions and levels of excavation for pouring the foundation in accordance with the project.Obtaining permissions

Preparations for the construction of power lines include obtaining permits from the authorities and owners of land through which the power line will pass.Access for construction crews to the place of work is provided through the construction of special access roads.

Construction site cleaning

This stage of work consists of cutting down trees and plants on the site for construction.Felled trees and any garbage from construction site are burned or taken to landfills approved by the authorities.

Earthworks and foundation pouring

At the next stage, excavation is carried out with the leveling of the site for pouring the foundation. Excess soil can then be used during construction work.When pouring the foundation, formwork can be used to provide sufficient resistance to pressure due to the placement of concrete and vibration. Steel reinforcement (rods, welded wire mesh and anchor rods or hooks) will be placed in accordance with the technical specifications.

Much attention is paid to the quality of concrete mixtures, which should be checked in specialized laboratories. Careful laboratory tests guarantee the strength of the foundations of power transmission towers.

Power transmission tower construction

The construction of power transmission towers requires the use of heavy cranes and trucks, which will deliver the elements to the place of preliminary assembly and installation.Before these works, access roads for heavy vehicles are being prepared.

Before assembling the power transmission towers, all surfaces of the connection are cleaned, and any dirt or mold that has accumulated during transportation and storage will be carefully removed.

Laying overhead power lines

Before laying power lines, a deep check of all structures is performed. A detailed project is drawn up indicating the length of the spans, types and location of all structural elements, and so on.After the installation is completed, a final check and test is carried out.

Modernization of thermal power plant

At the beginning of the 21st century, strict environmental standards and the depletion of fossil fuels are becoming key factors for the energy sector.New requirements are forcing owners to evaluate the effects of equipment aging and seek possible solutions to modernize their energy facilities.

Due to the growing global demand for energy and the serious problem of global warming due to greenhouse gas emissions, one of the main areas of research is improving the efficiency of thermal power plants and minimizing potentially hazardous emissions.

The effects of aging TPP equipment include:

• Reduced energy efficiency.

• Unrecoverable wear on equipment components.

• Reduced reliability and frequent unplanned stops.

• Increased equipment maintenance costs.

• Significant decrease in TPP operating profit.

• Increasing environmental impact, including greenhouse gas emissions.

The life of thermal power plants is usually 25-30 years.

In many developing countries, large thermal power plants were built at the end of the 20th century and have long been in need of modernization.

As a rule, outdated thermal power plants are inefficient.

The problem for the owners is the high operating costs, unsatisfactory environmental performance and dangerous wear and tear of equipment, which causes emergency situations and accidents.

Possible solutions to the problem of aging TPP equipment:

• Dismantling the power plant and building a completely new facility from scratch.

• Carrying out deep modernization and technical re-equipment.

Modernization of thermal power plants is aimed at improving the efficiency of old equipment and increasing generating capacity. It increases the reliability of TPPs, simplifies maintenance, and also allows the owner to use the land more efficiently.

Effects of the modernization of thermal power plant:

• Increasing the generating capacity of the power plant.

• Increasing the transmission of electricity through existing power lines.

• Obtaining competitive advantages in terms of the cost of electricity.

• Freeing up space on the construction site to install additional equipment.

• Improving environmental performance to avoid fines.

• Transition to more suitable types of fuel, etc.

There are various modernization schemes.

One of the most common methods is the installation of steam generators with heat recovery, transforming conventional thermal power plants into highly efficient combined cycle power plants.

Renewable energy can also be considered by integrating a solar thermal power plant into an existing TPP project.

A promising option is the introduction of solid oxide fuel cells.

The main areas of modernization of thermal power plants include:

• Re-equipment of existing boilers.

• In-depth modernization of the turbogenerator.

• Introduction of combined cycle technology.

• Integration of solar thermal power plants into the Rankine cycle.

• Integration of innovative fuel cells and many more.

Regardless of the modernization scheme, it is necessary to take into account the main technical, economic and environmental parameters, including:

• Thermal balance of equipment.

• Possible technical limitations of old equipment.

• Investment costs of the modernization project.

• Operating and maintenance costs.

• The operational flexibility of new equipment.

• Emissions of the thermal power plant, etc.

Around the world, a large number of TPPs are nearing the end of their useful life. Modernization of existing equipment is an attractive option for many owners to increase the efficiency, extend the life of the power plant and improve its environmental performance.

International EPC-contracting for construction of TPPs

Of all the engineering methods resulting from recent technological advances, EPC contracting best reflects the transformations that have taken place in this sector.This abbreviation means engineering, procurement and construction.

EPC clearly indicates everything that is included in the contract: engineering, supply of equipment and materials, construction. It also involves a number of additional services necessary to achieve the objectives of the project with minimal customer involvement.

This method of implementing energy projects has replaced the traditional tripartite relationship between the contractor, engineering firm and the customer.

Now customers can entrust turnkey construction of a facility to a single partner.

An EPC contractor is involved in design, tendering, procurement, construction, testing, commissioning, as well as training of personnel and other activities. In this type of contract, the emphasis should be on the fixed price and full responsibility of the contractor to the customer.

GCAM offers:

• Pre-project activities: a feasibility study, forecasting economic indicators, financial modeling, comparing various configurations, selecting a site for construction, preparing project requirements, etc.

• Engineering design of thermal power plants: preparation and approval of project documentation in accordance with customer requirements, equipment design and development of individual technical solutions.

• Selection and procurement of equipment necessary for the implementation of the project.

• Construction of a thermal power plant: preparation of a construction site, supply of materials and equipment, monitoring of construction and installation, testing and commissioning.

• Professional operation and maintenance of energy facilities.

• Comprehensive modernization, automation and implementation of new technologies.

GCAM and partners is involved in all matters related to the financing and design, construction, and modernization of thermal power plants anywhere in the world.

Our partners are experienced EPC contractors in the field of energy projects.

Our specialists will provide you with advisory support at all stages of the project.