After receiving the necessary documents and project presentation, our team will try to review your request as soon as possible, and leading experts will offer the best options for project funding.

A high degree of deterioration of equipment, unacceptable losses of electricity and insufficient automation of old TPPs impede the achievement of this goal.

Modernization of thermal power plants in accordance with the new requirements today is required by many enterprises in Europe and beyond.

Goals and directions of modernization of thermal power plants

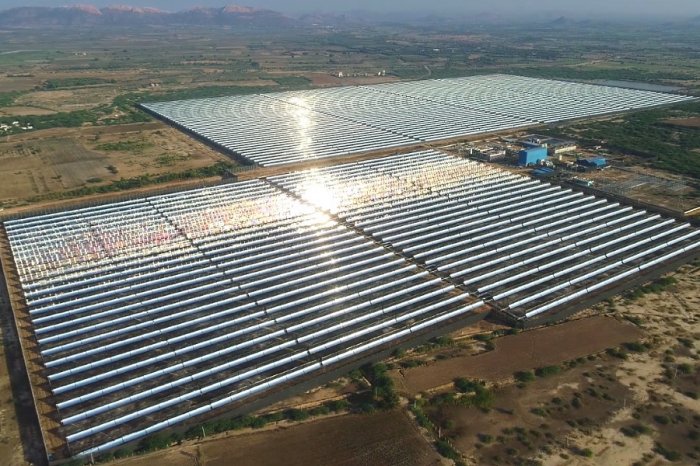

Currently, European countries are closing old thermal power plants that operate on heavy oil and coal.They are being replaced by more sustainable energy facilities using renewable energy sources, including solar photovoltaic plants and wind farms.

This creates new challenges for thermal power plants, including the need to work in conditions of frequent load changes associated with increased wear of equipment.

Tighter environmental regulations and the depletion of fossil fuels are forcing energy generating companies to seek new engineering solutions to improve energy efficiency and reduce emissions, especially NOx and SOx.

The main goals of modernization of thermal power plants:

• Extend the life of the equipment.

• Restore design parameters of technological systems.

• Reduce fuel consumption and minimize operating costs.

• Improve environmental performance in accordance with new regulations.

• Improve the reliability and stability of the TPP.

Restoring design parameters is a prerequisite for further electricity production, and compliance with environmental requirements avoids high fines.

Depending on the economic situation of the company and the possibility of selling electricity and heat, it is advisable to carry out comprehensive modernization of the facility with the simultaneous implementation of all of the above goals.

The most expensive and controversial goal of modernization is to increase efficiency.

With unchanged cycle parameters (pressure, temperature), a modification of the turbine can be of practical importance. Changing the profile of the blades, replacing seals, etc. Such solutions will increase the efficiency of the turbine by several percent.

If the goal is achieved with a relatively small investment, the benefits are undeniable. However, if we take into account the costly replacement of the rotor, then the economic efficiency of the project is doubtful. When determining the feasibility of these measures, the actual operating time of the turbine unit should be taken into account.

The greatest benefits can be achieved in the production of electrical energy and heat at the same time. Modernization of the turbine in this direction does not present serious technical problems, and significant economic benefits provide a quick return on investment.

The natural barriers to this modernization approach are the remote location of the power plant and the limited demand for thermal energy from nearby consumers.

An important goal is to extend the life of expensive equipment. In developing countries, the actual operating life of many power units of thermal power plants exceeds the standard operating life by several times.

Frequent load fluctuations and unplanned shutdowns complicate the situation.

Modernization of thermal power plants requires significant investments, but timely and well-planned measures can extend the life of equipment and improve overall performance.

When developing a TPP modernization program, several external and internal factors must be taken into account. They influence the choice of approach to the project.

External factors include forecasts regarding the economic situation in the national economy, trends in energy demand, energy costs, etc.

Internal organizational and technical factors create a much lesser degree of uncertainty.

A detailed study of the system of diagnostic, operational and repair procedures is part of our individual approach to the needs of each customer.

Theoretically, there are two approaches:

• One-stage modernization, with a complete renovation during a long downtime;

• multi-stage modernization, performed at several successive shutdowns of equipment.

Given the uncertainty of forecasts regarding the economic situation and conditions for the sale of electricity, the second approach may be more relevant. Our specialists will conduct a detailed feasibility study and suggest the best solution.

Assessment of the technical condition of a thermal power plant

Regardless of the initial goals of the customer, a key factor for making an economically sound decision is to assess the technical condition of the power units.This stage requires the systematization and analysis of the operating history, as well as comprehensive diagnostic tests and measurements. Particular attention is paid to the condition of the critical elements of the power unit (turbine, boiler, electric generator, main steam pipelines, etc.)

Assessment of the technical condition of the TPP power unit is important for predicting the suitability for further operation of critical elements and their reliability. Knowledge of the actual state of the metal, the real geometry of the structural elements, the actual operating conditions and the causes of damage is necessary to assess the resource of the elements.

The poor technical condition of these elements poses significant risks. Therefore, urgent measures are required as part of the modernization / repair program.

If the main goal of modernization is to increase the efficiency of the turbine, measurements should be made to prepare the heat balance of its individual elements before starting work.

Experience shows that the most difficult step in assessing the technical condition of a TPP power unit is the collection and analysis of retrospective data. Forecasting requires significant technical knowledge and experience.

The most important requirement is a correct assessment of the current state of the metal, requiring a detailed analysis of the design of the equipment and its working conditions.

The choice of sites for measurements should correspond to the location of the actual damage / wear zones.

This provides the most complete picture.

Programs for modernization and extension of service of individual equipment elements must comply with the condition of the power unit. The result of technical assessment and economic analysis serves as the basis for choosing the optimal modernization approach.

Any costly modernization measures should be economically viable.

Modernization of power boilers of thermal power plants

Improving the energy efficiency of thermal power plants usually includes the modernization of boilers, in particular, the installation of highly efficient burners, valves and automation. As part of the modernization, a change in the power of the equipment is possible.Experts provide a full range of engineering and technical services related to the modernization of boilers of thermal power plants.

Many TPP power units in Asia, Africa, South America and Eastern Europe are currently ineffective, some are completely worn out and require urgent measures. An individual client-oriented approach is aimed at improving the safety and operational efficiency of old boilers.

Installation of modern burners and automation reduces fuel consumption, improves environmental performance and optimizes operating conditions. Properly selected and installed equipment of leading world manufacturers provides smoother regulation of the operating parameters of boilers.

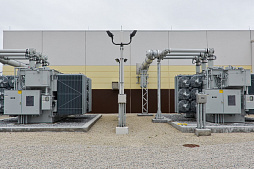

Modernization of generators of a thermal power plant

Improving the efficiency and profitability of thermal power plants directly depends on the efficiency of electric generators.

Our company provides comprehensive services for the modernization of generators, including design, procurement and installation of new equipment, as well as testing and commissioning.

New environmental requirements and the development of renewable energy have changed the requirements for the operation of thermal power plants.

Engineers will help prepare your facility for the challenges of the future.

Specialists develop innovative technologies in the energy sector and integrate modern technical solutions into existing thermal power plants. Customer's economic interests, sustainability, energy efficiency and safety are our priorities.

Thanks to our solutions, customers improve equipment performance, reduce air emissions, increase maintenance intervals and make maintenance more flexible.

Our company, together with its partners, offers financing and a wide range of options for the modernization of TPP electric generators taking into account the specific needs of your business.

Contact our consultants to learn more about services in this area.

Wireless technologies and monitoring systems for TPPs

Currently, most of the maintenance and operation of thermal power plants is carried out manually.A business loses money as a result of breakdowns and unplanned equipment shutdowns. Atmospheric emissions are not always up to standard, and steam energy is wasted due to undetected leaks.

The smart power plants of the future are based on 100% automated monitoring systems that keep equipment in perfect condition with minimal intervention. Wireless sensors and computers detect problems in the early stages, increasing the safety and reliability.

To facilitate the work of maintenance teams, the company offers a number of unique solutions for the automation of thermal power plants. These technologies are in demand at facilities that operate under conditions of load fluctuations caused by the spread of renewable energy sources.

The cyclic mode of operation with frequent stops creates unfavorable conditions for the equipment and accelerates its wear by 1.5-2.5 times. This requires careful monitoring and maintenance.

Unfortunately, not all equipment has protection. To monitor the condition of cooling towers, pumps and other equipment, manual checks are periodically conducted.

Wireless technologies replace time-consuming manual operations and increase monitoring efficiency. Thanks to wireless sensors, engineers can monitor all the equipment of the thermal power plant from the control room.

One such solution is a wireless vibration sensor, which is mounted on rotating equipment for continuous monitoring of its condition.

Along with vibration sensors, modern TPPs use more sophisticated multi-parameter monitoring systems that cover several indicators at once. The introduction of such systems provides continuous monitoring of fluid flow, temperature, pressure, conductivity and other important parameters.

Multiparameter monitoring systems help prevent breakdowns and save hundreds of thousands of dollars on unplanned stops and equipment repairs.

Engineers of our company develop individual technical solutions for automation and monitoring for thermal power plants. As the experience of our customers shows, these investments pay off quickly.

Automatic monitoring and tuning of the operating parameters of thermal power plants contributes to increased productivity.

Control and monitoring systems transform the industry.

Old power plants can be easily upgraded by deploying these systems to improve the reliability, safety and energy efficiency of the facility.

Effects of thermal power plant modernization

| Modernization of TPP boiler | Water heater modernization | Hybrid modernization | Complete modernization | |

| Power increase | < 50% | < 25% | < 50% | < 50% |

| Efficiency increase | < 20% | < 10% | > 40% | > 50% |

Our services for the modernization and maintenance of TPPs

Thanks to the use of the best European technologies and advisory support for the implementation of turnkey projects, our company helps investors to achieve the desired results.Specialists manage all aspects of thermal power plant projects, including a feasibility study, financing, design, construction, wiring, testing and commissioning of equipment.

Detailed planning is the key to successful modernization.

We provide customers with full support from the very beginning, using our experience in financing energy projects.

An experienced technical support team ensure stable operation of energy facilities and reduce downtime to a minimum. For this, there is the necessary knowledge and technology to effectively manage TPPs throughout the entire life cycle.

The company's engineers can avoid problems by identifying vulnerabilities long before potential power plant failures.

A wide range of services for the design, modernization and maintenance allows our customers to optimize operating parameters and increase the life of thermal power plants and equipment.

Contact our consultants for more information on financing and modernization of TPPs.