After receiving the necessary documents and project presentation, our team will try to review your request as soon as possible, and leading experts will offer the best options for project funding.

Self-generated energy, the introduction of highly efficient production lines and innovative wastewater treatment technologies are extremely important for the sustainable development of the pharmaceutical and chemical industries.

GCAM with its partners offers a full range of investment and engineering services for the modernization of chemical plants..

Specialists are ready to develop individual solutions to improve the quality and reduce the cost of chemical production.

To learn more about our services, contact us at any time.

Chemical plant modernization

Today, the chemical industry accounts for about 20% of all energy used by European industry.This energy is used to turn raw materials into useful chemical products through reactions and purification processes. A significant proportion of this energy is generated from hydrocarbons, mainly from natural gas and oil.

The energy efficiency of chemical plants in many developing countries remains low, which negatively affects the competitiveness of businesses. Chemical plants are looking for ways to minimize the amount of fuel and electricity consumed.

The main approaches to improving energy efficiency include improving the chemical purity of products, the intensification of technological processes, the introduction of recycling technologies, investments in renewable raw materials and electricity generation.

Engineers apply the latest methods of modeling, control and intensification of technological processes to increase the energy efficiency of chemical plants.

Modeling, optimization and control of chemical production

One of the recent achievements in the chemical industry is the introduction of new methods of modeling, optimization and production control.Typically, process control involves monitoring and adjusting parameters such as temperature and pressure. Our experts can develop highly effective forecasting models for various parameters to increase the efficiency of chemical production.

This approach is aimed to set the most favorable parameters, taking into account economic, environmental and other factors. There are many parameters, including reactor temperature, pressure, flow rate, and the composition of reaction intermediates.

Since the chemical plant is an extremely complex system with non-linear and multidimensional relationships, the ordinary operator is not able to set the best conditions for each situation.

For example, restarting equipment with multiple recirculation flows may take several days to reach full production capacity. Effective process modeling reduces this time by at least half.

Another area of modernization of chemical plants is to reduce the burning rate of gases and liquids. Fast burning with excessive fuel consumption occurs in cases of violation of operating conditions (for example, overpressure), as well as in the event of equipment breakdowns.

The installation of safety valves and other protective equipment reduces fuel consumption, increasing the overall efficiency of the enterprise.

Another problem is the production of chemical by-products that cannot be recovered, stored or refined. This usually occurs when process failures or reactors restart.

Improving the stability of technological processes and the introduction of effective methods of purification, storage and use of by-products save significant costs.

One promising approach is to replace gas turbines. Despite their high efficiency, gas turbines are more complex than steam turbines. In addition, gas turbines are likely to cause process failures.

Another saving option is the introduction of gas recirculation technologies.

Improving chemical production efficiency

The intensification of chemical production involves a set of innovative principles in the design of processes and equipment that can bring significant benefits in terms of efficiency, capital costs and operating costs, product quality, waste reduction and much more.

The most commonly used chemical and physical processes have significant limitations on mass or heat transfer. Thus, distillation column limitations are associated with relatively low gravity.

Increasing the driving force of rotary equipment can significantly reduce economic costs and energy consumption. However, the implementation of such measures requires considerable effort.

Despite some improvements achieved for specific processes, the full-scale implementation of innovative technologies often requires the replacement of obsolete equipment and a thorough review of energy-intensive stages of production.

There are a number of obstacles to their implementation, including the cost of upgrading existing facilities, and the lack of practical experience and technology.

Undoubtedly, the design of a new chemical plant gives engineers much more freedom than the modernization of obsolete production facilities.

Measures to increase the efficiency of chemical production include:

• modernization and replacement of equipment, including reactors and furnaces, intensive mixing devices and heat exchangers;

• modernization of basic technological processes, including chemical reactions and product separation, heat transfer and phase transitions;

• introduction of innovative methods for managing chemical production;

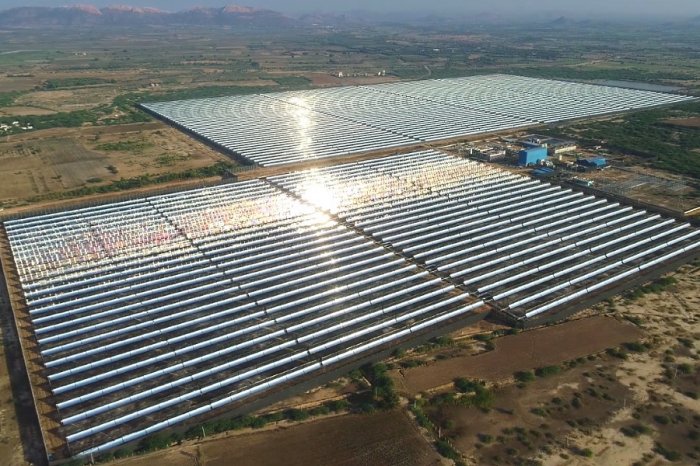

• use of alternative energy sources.

During modernization, innovative heat exchangers, mixers, spinning disk reactors, and other technological solutions are developed.

Introduction of energy recovery technologies

It is estimated that up to 50% of the energy used in the chemical industry is lost in the form of exhaust gases, cooling water and heat loss from equipment and products.Energy optimization usually covers several areas. Their implementation will depend mainly on economic feasibility and potential technical risks for a particular production process.

Factors such as the time interval between the use of heat and its generation, as well as the constant availability of heat sources, should be taken into account when upgrading equipment. To implement this approach, we use cost-effective energy storage and energy management technologies.

Improving the energy efficiency of chemical plant includes:

• the use of pinch analysis at all stages of chemical production;

• installation of highly efficient heat pumps, heating and cooling systems;

• the use of the organic Rankine cycle for the optimal use of thermal energy;

• increasing the efficiency of heat exchange between different companies in the same industrial zone or between district heating networks.

Pinch analysis finds the optimal balance between demand and supply of heat, taking into account the use of energy storage systems. The introduction of this method in chemical plants gives up to 20-30% fuel savings.

The modernization of chemical production involves increasing the efficiency of waste heat, as well as the widespread introduction of equipment that runs on waste heat instead of steam and electricity.

Particular attention is paid to increasing heat transfer, especially at high temperatures, in dusty and chemically aggressive environments. Cascade heat pumps are also a promising alternative.

In the chemical industry, heat from high-temperature objects such as furnaces is regenerated in the form of excess pressure steam. This steam is used to operate energy-consuming compressors and other equipment. Residual steam is used at lower pressures for other purposes.

Heat pumps can increase the temperature of steam. But the potential of heat pumps is limited, because some processes will require steam with too high a temperature.

To solve this problem, innovative systems such as thermochemical heat pumps or thermo-acoustic heat pumps are offered today. The cost of introducing the organic Rankine cycle is still high compared to other methods of energy production, but this technology is also improving.

Waste heat from chemical plants can be sold to other users, including district heating systems.

This opens up new opportunities for chemical plants.

Efficient use of electrical energy

Electric motors are the main consumers of electricity in the chemical industry.They use almost 70% of the total amount of electricity, if you do not take into account energy for chemical reactions.

Electric motors are predominantly used to operate pumps, fans, compressors and other equipment. Their effectiveness depends not only on the parameters of the engine itself, but also on such factors, as electrical losses, proper control, maintenance and other aspects.

The main approaches to saving electric energy are:

• choosing electric motors of a suitable type;

• using drives that can adjust the speed in accordance with the requirements of the system;

• full energy system optimization, including the elimination of unnecessary reverse flows, pipelines and other equipment.

Practical experience shows that the introduction of efficient electric motors during the modernization of chemical plants can save up to 30% of electric energy.

Self-produced energy

Many chemical plants currently produce heat and electricity for their own needs. However, these technologies need constant modernization in accordance with modern requirements.For example, measures to improve the efficiency of boilers reduce fuel consumption by 3-10%. Typically, measures include improved process control, flue gas recirculation (FGR), and regular equipment maintenance according to standards.

Condensate recovery, prevention of heat loss in distribution systems and other measures save up to 5% of energy, and improved insulation of pipelines gives additional savings of about 2-3%.

However, it should be noted that the potential of these measures in the field of energy efficiency depends on the specific object.

Customized power generation solutions for the chemical industry are being developed.

New energy and resource management concepts

Optimization of interaction between enterprises within industrial zones contributes to a significant increase in the energy efficiency of chemical production and reduction of carbon dioxide emissions.More efficient energy and resource management systems within the industrial zone involve the use of decentralized energy resources. These systems should apply standardized approaches to optimize the demand and delivery of energy and resources based on innovative analytical tools.

Outside the industrial zone, close interaction between companies and neighboring municipalities can bring a lot of economic advantages to a chemical plant.

Wastewater treatment in chemical industries

Most of the wastewater in the chemical industry is generated as a result of basic technological processes.Wastewater is generated both during chemical reactions (for example, during condensation), and during subsequent treatment of the synthesized compounds.

The final and / or intermediate products at each stage of the synthesis are isolated and purified by filtration, centrifugation, distillation and other methods.

Waste water after chemical synthesis may include mother liquors, water purification products, condensation water, cooling water, waste water from equipment washing, etc.

Such wastewater contains all kinds of pollutants resulting from chemical reactions, such as unreacted feedstock, additives, unwanted by-products.

If the synthesis is carried out using organic solvents, they make up a significant part of the organic fraction entering the treatment plant. They form a complex wastewater biodegradable fraction.

About 80-90% of chemical wastewater consists of streams with a low level of pollution, while the remaining 10-20% (mother liquors, condensates) are characterized by a high concentration of pollutants that are potentially harmful to the environment and human health.

Large-scale environmental initiatives have been launched in recent decades around the world. As a result, regulatory documents containing stringent requirements for industrial emissions were developed and adopted.

A new approach to environmental protection necessitates investing in cleaner technologies and more efficient wastewater treatment plants.

Chemical industry

The first step in wastewater treatment from the chemical industry is the separation of suspended solids and water-immiscible liquids from the wastewater stream.Highly efficient separation and clarification technologies are used, including gravity separation, flotation and filtration. These technologies are usually used in combination with other methods at different stages of the water treatment process.

Technologies for the removal of biodegradable contaminants from wastewater are based on physical or chemical processes, such as precipitation and filtration, crystallization, membrane filtration, adsorption, ion exchange, extraction, distillation and rectification, evaporation.

Biological treatment of chemical wastewater does not always cope with some pollutants:

• diethylene glycol dimethyl ether;

• chelating agents such as EDTA and DTPA;

• cyclic ethers, in particular dioxanes;

• bleaches, such as dinitrosalicylic acid;

• oligomers from the production of polyacrylonitrile and methyl cellulose;

• perfluorooctanesulfonic acid and other perfluorinated compounds;

• iodine-containing agents, including iopamidol, as well as some organic pigments;

• methyl tert-butyl ether (MTBE) and other substances.

Chemical wastewater contaminated with biodegradable substances is usually biologically treated.

These approaches are based on biological processes, such as:

• aerobic treatment in a membrane bioreactor using different technologies;

• anaerobic digestion (anaerobic contact process, activated sludge process);

• nitrification / denitrification and other processes.

After proper treatment, the chemical plant's wastewater stream can be discharged to the receiving body of water or sent for further biological treatment at urban wastewater treatment plants (UWTP).

Pharmaceutical industry

The composition of the wastewater of pharmaceutical plants varies widely depending on technological processes, productivity and much more.These factors determine an individual approach to the design of wastewater treatment systems.

The main groups of pollutants in the wastewater of pharmaceutical plants include:

• organic substances, mainly biodegradable (alcohols, acetone);

• slowly biodegradable organic compounds and soluble substances (aromatic compounds, chlorinated hydrocarbons);

• complex highly toxic compounds (cytostatics, antibiotics);

• surfactants and many others.

The choice of pharmaceutical industry wastewater treatment technology depends on the particular case, given the significant variety of manufacturing processes and chemicals used.

Modern technologies include biological treatment in moving bed bioreactors and vacuum evaporators, as well as anaerobic digestion processes, oxidation processes, and so on.

When wastewater is suitable for biological treatment and the organic matter content is high, moving bed biofilm reactors are considered the most appropriate option.

Microorganisms form a thin biofilm on the surface of plastic balls that constantly move in the reactor. Granules have a large specific surface area, which contributes to the growth of more microorganisms per unit volume than in conventional reactors.

Due to the large specific surface area of the granules, new bioreactors are smaller than plants that use activated sludge. Another advantage is that the process can be divided into several stages with a specific type of microorganism at each stage. Exceptional flexibility allows for the efficient decomposition of the most persistent pollutants.

However, biological processes are not effective enough in the treatment of heavily contaminated wastewater from pharmaceutical and chemical plants. Due to their persistent, toxic components and low biodegradability, highly efficient vacuum distillation technologies can be used.

When wastewater has a high concentration of persistent pollutants, toxic or non-biodegradable substances, treatment processes are required to ensure more intensive decomposition of pollutants.

The term Advanced Oxidation Process refers to a wide range of technologies based on the formation of radicals or the supply of energy to break down molecules of industrial pollutants. Such technologies are relevant for the removal of halogenated hydrocarbons, surfactants and pigments.

Modern pharmaceutical plants actively use electrochemical oxidation, catalytic ozonation, anodic oxidation, a combination of UV radiation and exposure to hydrogen peroxide, the Fenton reaction and photocatalysis.

Due to the non-selective nature, these methods can be used to treat heavily contaminated wastewater with any pollutants, but their implementation is expensive.

An individual approach is applied to the choice of technical solutions for the modernization of pharmaceutical production. It takes into account the specifics of a particular business and customer requirements, as well as current national and international standards.

Cosmetics industry

Cosmetic wastewater contains many different compounds, both organic and inorganic.Unfortunately, the real problems of wastewater treatment in the cosmetics industry are not well understood. The reason for this may be the erroneous assumption that the wastewater components of the cosmetic industry are low toxic and easily decomposed by microorganisms.

In fact, the substances found in the wastewater of cosmetics and perfume factories resemble the wastewater of the pharmaceutical industry. This includes complex biologically active molecules, excipients and intermediate products of their synthesis.

These substances can be highly toxic to humans and the environment. Often they accumulate in the components of the ecosystem, where they exist for years and even decades.

Organic substances include hydrocarbons, proteins, ethers, esters, aldehydes, ketones, alcohols, carboxylic acids, as well as their complex derivatives and products of biochemical reactions. Inorganic substances include acids, alkalis, salts, oxides and compounds of heavy metals.

These substances play different roles in cosmetics.

They can serve as a basis (carrier) or act as an active substance. Active ingredients include moisturizers, flavors, surfactants, antiseptics, colorants, vitamins, UV filters and more.

The wastewater of the cosmetics industry is characterized by very high COD (chemical oxygen consumption), BOD5, as well as a high content of organic carbon, ethers, organic nitrogen and phosphorus.

The most widely used method of wastewater treatment in the cosmetics industry is biological. However, its results may be unsatisfactory, especially when the concentration of fats is high.

The reason for the low efficiency of biological treatment is the high variability of the chemical composition of pollutants. Since many substances contained in wastewater are slowly biodegradable, they must be pretreated.

Wastewater treatment technology include physicochemical methods such as coagulation, flotation and electrocoagulation, oxidation, membrane processes. In some cases, good results are achieved using modern oxidation technologies.

Chemical plant financing and modernization services

The need for continuous modernization of chemical and pharmaceutical plants today is becoming apparent to businesses.Optimization and automation of chemical production is especially important in the era of the massive introduction of digital technology.

Many large chemical plants in developing countries need reconstruction and improvement. Outdated equipment and imperfect technological processes adversely affect energy efficiency, productivity, quality and cost of production.

Engineers are ready to use their vast experience and unique technologies to make your business more profitable and competitive.

Numerous customers in Europe, North Africa, South America and the Middle East have appreciated the high quality of our financial and technical services.